Ultrasonic sensors utilize electrical power, as well as a ceramic transducer to produce, as well as receive, power in the kind of sound waves. Sound waves are basically stress waves that travel via liquids, solids, and gases, as well as can be utilized in industrial applications to measure distance or spot the visibility or absence of targets. These FAQs answers some typical questions about ultrasonic sensors, concept, as well as terms.

What are ultrasonic sensing units?

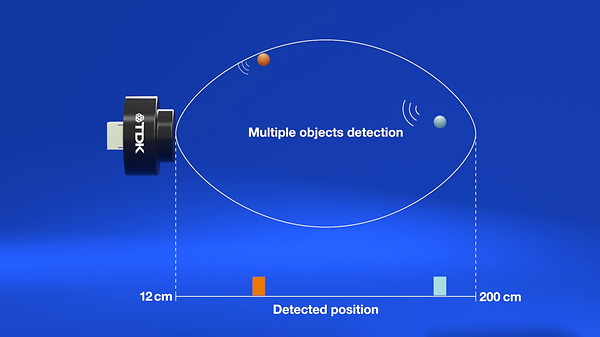

Ultrasonic sensors are industrial control tools that utilize acoustic waves above 20,000 Hz, beyond the range of human hearing, to determine the distance from the sensing unit to a defined target object.

How do ultrasonic sensing units function?

Ultrasonic sensor technology has ceramic transducers and they vibrate when electric power is put on them. The vibrations compress as well as increase air molecules in waves from the sensing unit face to a target thing. A transducer both transfers, as well as obtains noise. The ultrasonic sensor will determine distance by sending out a sound wave and then “listening” for a set of time, permitting the return resemble of the sound wave jumping off the target, prior to retransmitting.

When would I utilize an ultrasonic sensor?

Because ultrasonic sensing units use audio as opposed to light for detection, they work in applications where photoelectric sensing units may not. An ultrasonic sensor is a great option for clear item discovery, as well as for liquid degree measurement, apps that photoelectric sensors scuffle with as a result of target transparency. Target shade and/or reflectivity don’t influence ultrasonic sensors which can operate accurately in high-glare atmospheres.

When should I utilize an ultrasonic sensing unit versus an optical sensor?

Ultrasonic sensors use benefits when sensing clear things, fluid levels, and highly reflective, or metal surfaces. Ultrasonic sensors additionally function well in damp settings whereas an optical beam might refract off the droplets of water. But ultrasonic sensors are at risk of temperature changes or wind. With optical sensors, you can have a little spot dimension, and quick reaction, as well as in some circumstances, you can project a visible spot on a target to aid with sensor placement.

How do ultrasonic sensing units handle sound and also interference?

Any type of acoustic sound at the regularity to which the ultrasonic sensor is responsive may disrupt that sensor’s output. This consists of high-pitched sounds such as those produced by a whistle, the hissing of a safety valve, pressed air, or pneumatically-driven tools. You may also get acoustical crosstalk by situating two ultrasonic sensing units of the same regularity close to each other. An additional sort of sound, electrical sound, is not special to ultrasonic sensing units.