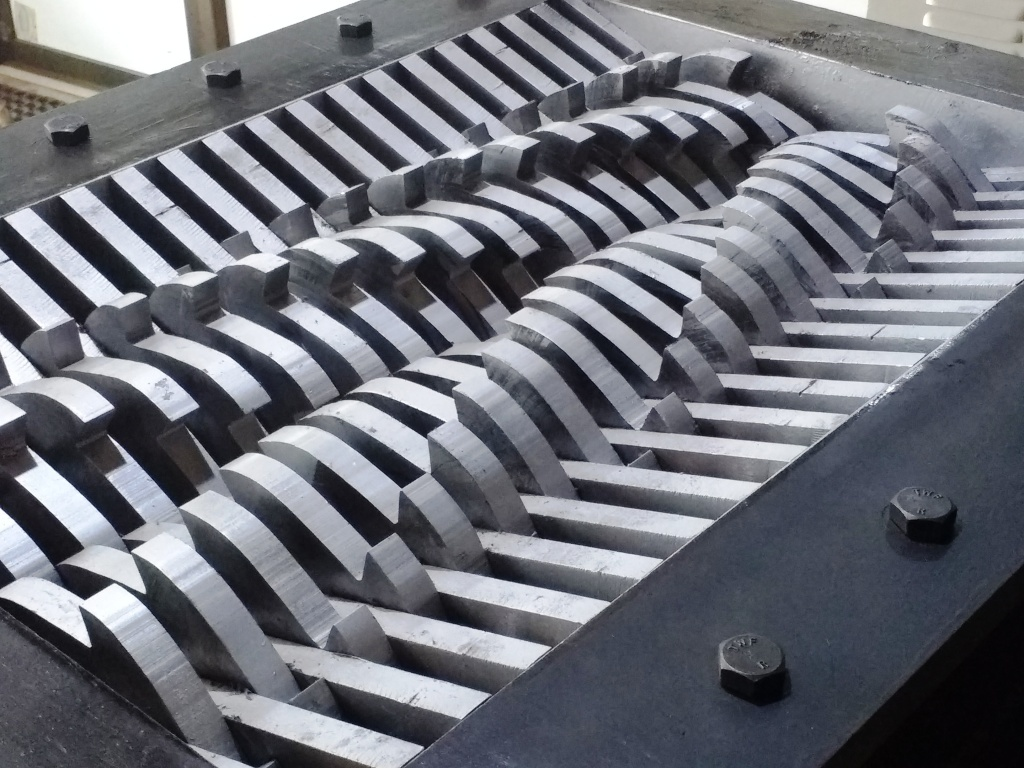

Have you ever had to wonder what it takes to break huge, heavy materials into sizable sizes? Have you ever thought of the possibility of breaking strong materials into pieces? The way out is the industrial shredder. It is very much possible to have heard about Industrial Shredder but not know the purpose. In the waste management industry, these industrial shredders are used in wide disposable systems, used by recycling units and municipal equipment. Ranging from asphalt and transforming rubber to plastics and wood. It maximally compacts large volumes of waste into minute rations of the actual sizes in a couple of minutes. When they are used at landfills, these shredders essentially reduce the waste quantity and also increase the decomposition of biodegradable waste.

Checking into the current eco-conscious business environment, it is indisputably recognized that Industrial Shredders give an impeccable opportunity to businesses looking into cutting costs. However, it is not only useful in the recycling processes to reduce voluminous materials but also helps to reduce transportation and storage costs. For example, shredding tires, which is one of the fastest-growing business opportunities around the world, reduces transportation costs by 75%. Transportation of tires intact is very expensive, costing thousands of euros more on an annual basis. Shredding tires cut transportation costs by 75% by allowing about four times the rate of material expected to be loaded for one trip. It is quite unfortunate that the transportation of intact tires is expensive and most of the airspaces are lost due to the type of tire; this is apparently far from the ideal angle of logistical perspective. In fact, this was one of the reasons Italy requested minimization of the cost of scrap tire transportation with the goal of eliminating the loss of valuable airspace and making pre-shredding processes cost-efficient.

It is indisputable that Industrial Shredders play a vital role in fragmenting common materials such as plastic and also prepare these materials for blowing and/or injecting moulding processes. All these contribute to the preparation of plastics for extrusion processes. Injection moulding is mostly and widely used for plastic processing all over the world and is mostly done with specialized injection moulding machines. This will automatically make high volume, high–quality part production possible. With the injecting moulding process, there is efficient management and re-use of scrap fragmented materials, proper removal, and the handling of the finished parts.